ModerneTre

Sample and Materials

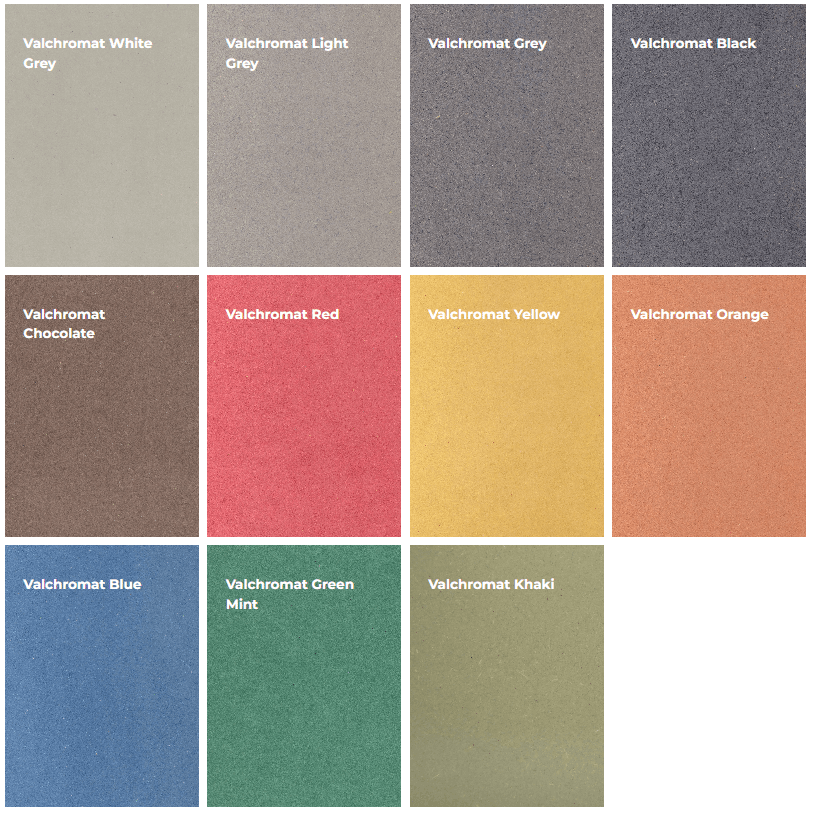

Valchromat

Valchromat stands out as a remarkable innovation in the world of wood fibreboard, rising above conventional MDF through superior properties, especially as MDF.HLS (Medium Density Fiberboard – Hydrophobic). This mass-coloured wood fibreboard is not only visually appealing, but also offers exceptional physical and mechanical performance thanks to a unique manufacturing process.

Unlike traditional MDF, Valchromat features fibres that are individually impregnated with organic dyes and bonded together with a special resin. This unique approach gives Valchromat a distinctive composition, resulting in unique physical and mechanical characteristics. This exclusive formula not only provides a rich palette of colours, but also makes it possible to execute three-dimensional works with ease.

Valchromat, like MDF.HLS, not only offers moisture resistance, but also stands out for its versatility in a variety of applications. Compared to other types of MDF, its superior properties make it ideal for interior design, furniture and construction projects that require exceptional durability and performance.

Valchromat’s added value goes beyond its vibrant colour to its distinctive composition and ability to overcome the challenges faced by other similar materials. Whether for environments subject to humidity or for creations requiring a more creative, three-dimensional approach, Valchromat stands out as an unrivalled choice, offering not only aesthetics but also superior performance compared to many MDF applications.

Plywood is a composite material manufactured from thin layers, or „plies”, of wood veneer that are glued together with adjacent layers, having both glued with each other at right angle. It is an engineered wood from the family of manufactured boards, which include plywood, medium-density fibreboard (MDF), oriented strand board (OSB), and particle board (or chipboard).

Softwood plywood made from spruce.

The principle of making plywood.

All plywoods bind resin and wood fibre sheets (cellulose cells are long, strong and thin) to form a composite material. This alternation of the grain is called cross-graining and has several important benefits: it reduces the tendency of wood to split when nailed at the edges; it reduces expansion and shrinkage, providing improved dimensional stability; and it makes the strength of the panel consistent across all directions. There is usually an odd number of plies, so that the sheet is balanced—this reduces warping. Because plywood is bonded with grains running against one another and with an odd number of composite parts, it has high stiffness perpendicular to the grain direction of the surface ply.

Deer

Deer